Platform Supply Vessels can transport up to 10,000 cubic meters of supplies to offshore platforms – enough to fill four Olympic-sized swimming pools! These specialized ships are the workhorses of the offshore industry, delivering everything from fuel to massive equipment.

Ocean-Going Lifelines: The Maritime Workhorses

Platform Supply Vessels (PSVs) are the backbone of offshore operations. These special ships move critical supplies between land and offshore installations like oil rigs and wind farms. Without PSVs, offshore energy production would simply stop.

Whether bringing fuel to drilling platforms or delivering massive wind turbine parts, PSVs keep the offshore world running. Let’s explore the amazing variety of cargo these vessels transport every day.

What is a Platform Supply Vessel?

Platform Supply Vessels are specially designed ships that support offshore operations. Modern PSVs typically have open deck areas larger than 1,000 square meters, below-deck tank capacity between 5,000-10,000 cubic meters, and cranes that can lift between 50-250 metric tons.

These vessels are built to handle rough seas while carrying heavy and sometimes dangerous cargo. They connect offshore platforms to land, bringing everything workers need to live and work at sea.

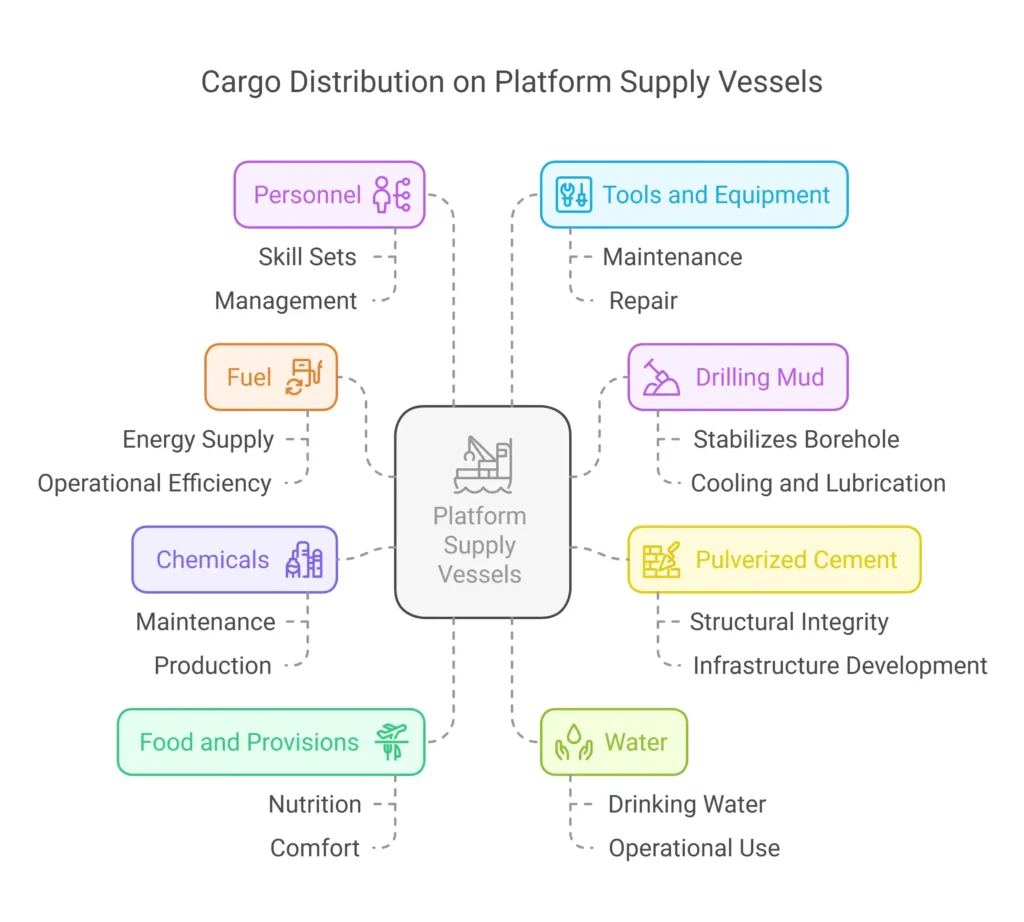

Liquid Cargo Types

About 60% of a PSV’s below-deck space is dedicated to liquid storage. These liquids are essential for offshore operations.

Fuels and Oils

Marine Gas Oil (MGO) is the most common liquid cargo on PSVs. This diesel fuel powers platform generators, support vessels, and emergency equipment.

PSVs transport 40-50% of their liquid cargo as fuel. Modern vessels have special double-hulled tanks to prevent spills, following international safety rules.

Water Supplies

Offshore platforms need fresh water for drinking, cooking, showers, and some industrial processes.

In dry regions like the Middle East, PSVs might deliver up to 3,000 cubic meters of water per trip. The water travels in special food-grade stainless steel tanks to keep it clean.

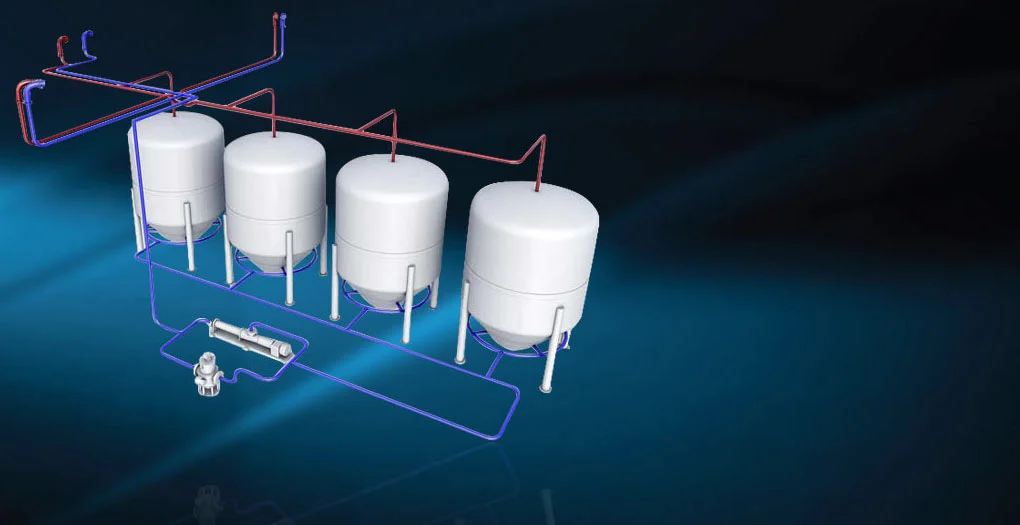

Drilling Fluids

Oil and gas drilling requires special fluids called “mud.” PSVs carry water-based mud, synthetic-based mud, and completion fluids.

These fluids help cool drill bits and remove rock cuttings during drilling. PSVs need special pumping systems to move these thick liquids.

Dry Bulk Materials

PSVs carry large amounts of dry materials needed for drilling and construction.

Cement and Barite

Cement is essential for securing well casings in drilling operations. For example, drilling operations in Brazil’s Santos Basin use about 15,000 metric tons of cement every month.

Barite is a heavy mineral that helps control pressure in drilling fluids. PSVs transport these materials in pressurized containers to keep them dry.

Sand and Proppants

For certain oil and gas operations called “fracking,” PSVs deliver special sand called proppant. A single PSV voyage to the Gulf of Mexico might carry more than 5,000 metric tons of this special sand.

These dry materials move through special pipes and systems that prevent dust from escaping into the air.

Equipment and Machinery

The large open decks of PSVs make them perfect for moving big equipment to offshore sites.

Subsea Equipment

PSVs transport underwater equipment such as remotely operated vehicles (ROVs), Unmanned Underwater Vehicles (UUVs), blowout preventers (BOPs), subsea manifolds, and drill pipes.

For example, a typical North Sea PSV might carry twelve 30-inch drill pipes (18 metric tons each), a 400-metric ton subsea manifold, and eight ROV skids with control cabins.

During Norway’s Johan Sverdrup field expansion in 2024, PSVs delivered 15,000 metric tons of subsea equipment. They maintained less than 0.5 degrees of deck tilt during these operations.

Containers and Parts

Standard shipping containers (20ft and 40ft) are common on PSV decks. These containers hold spare parts like pump assemblies and valve stacks, electronic equipment including control systems and sensors, and safety gear and medical supplies.

PSVs serving West African offshore fields typically carry 40-60 containers per trip. These containers use special twist locks and lashing bridges to stay secure during rough weather.

Specialized Cargo

As offshore industries evolve, PSVs handle increasingly specialized cargo.

Wind Energy Components

In the North Sea, PSVs now regularly transport wind turbine parts such as 80-meter turbine blades on custom cradle systems, transition piece grout materials, and heavy high-voltage cable reels weighing up to 2,000 metric tons.

The Dogger Bank Wind Farm project shows these new cargo demands, with PSVs transporting 15 giant 14MW turbine nacelles per voyage.

Emergency Supplies

During hurricane season in the Gulf of Mexico, PSVs carry storm anchors weighing 500-1,000 metric tons, emergency fuel (10,000+ barrels per day), and mobile accommodation modules for evacuation crews.

These emergency operations require PSVs to load and move quickly when storms approach.

New Trends in PSV Cargo

As offshore industries evolve, PSVs are adapting to transport greener materials and alternative fuels. Learn more about the latest offshore technology advancements.

Green Energy Materials

As renewable energy grows, PSVs transport biodegradable hydraulic fluids, composite cable protection systems, and carbon capture modules weighing 3,000 metric tons.

PSV operators are installing larger 500-ton active heave compensated cranes to handle these bigger components.

Alternative Fuels

The push for cleaner energy affects PSV cargo. The vessels now carry liquid hydrogen in special cryogenic tanks (-253°C), ammonia fuel systems requiring nickel-alloy pipelines, and segregated chemical tanks for methanol.

New regulations coming in 2025 will require all PSVs operating in emission control areas to have separate biofuel storage tanks.

Final Thoughts

Platform Supply Vessels are truly the lifeline of offshore operations. From traditional fuels and drilling materials to cutting-edge renewable energy components, PSVs transport an incredible variety of cargo in challenging conditions.

As offshore operations move into deeper waters and harsher environments, PSVs continue to evolve. New designs focus on carrying alternative fuels, larger components, and more specialized equipment.

Whether supporting oil and gas operations or helping build the renewable energy future, Platform Supply Vessels remain essential to the offshore supply chain and global energy production.

Want to learn more about the offshore industry and its specialized vessels? Check out our related articles on offshore operations and maritime logistics.

Leave a Reply