The Sterntubeless Ship Concept: Revolutionizing Maritime Technology

The sterntubeless ship concept, pioneered by Thordon Bearings, is revolutionizing the maritime industry. The T-BOSS design, launched in September 2024, eliminates the need for oil-lubricated sterntube seals and bearings, offering significant savings and environmental benefits. This article delves into the concept, its development, global interest, compliance, and future prospects.

Overview of Sterntubeless Ship Concept

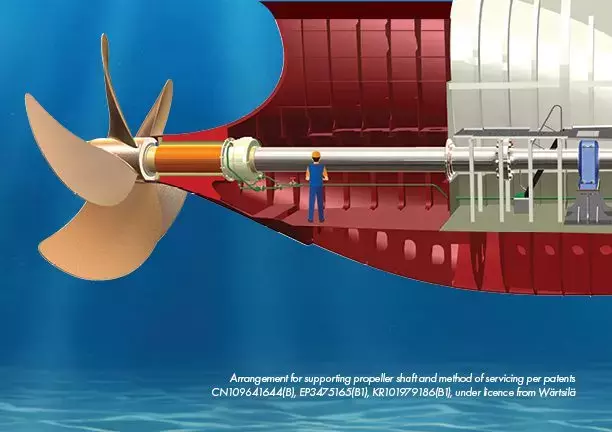

The sterntubeless ship concept represents a groundbreaking advancement in maritime technology, addressing the limitations of traditional sterntube designs. This innovative approach involves replacing the conventional sterntube with a seawater-lubricated bearing system, which eliminates the need for oil lubrication and the associated maintenance challenges. The sterntubeless design features a shorter, water-lubricated propeller shaft that can be easily inspected, reducing downtime and enhancing operational efficiency [Source: Case Study for Sterntubeless Design].

The concept addresses several critical issues faced by traditional sterntube designs. Oil-lubricated sterntubes are prone to leaks and contamination, which can lead to environmental damage and costly repairs. In contrast, the sterntubeless design uses seawater as a lubricant, eliminating these concerns and ensuring a cleaner ocean environment [Source: ABS-Approved Sterntube-less Ship Concept to Save Shipowners Thousands While Keeping Oceans Clean].

Key milestones in the evolution of the sterntubeless ship concept include the introduction of seawater-lubricated bearings and the development of the T-BOSS design by Thordon Bearings. The T-BOSS design, officially launched in September 2024, represents a significant advancement in this field. It features a seawater-lubricated bearing, a Wärtsilä forward shaft seal, a Water Quality Package, and a bulkhead seal, making it a comprehensive solution for modern shipping needs [Source: All New Ships Should Be Built to a Seawater-Lubricated Sterntubeless Ship Design].

Introduction to Thordon Bearings and T-BOSS Design

Thordon Bearings, a pioneering force in maritime technology, has established itself as a leader in the development of the sterntubeless ship concept. With a background rooted in over five decades of expertise in bearing technology, Thordon Bearings has consistently pushed the boundaries of what is possible in maritime engineering. Their innovative solutions have been instrumental in advancing the sterntubeless ship design, which aims to revolutionize the way ships operate and interact with the marine environment [Source: Case Study for Sterntubeless Design].

The T-BOSS design, developed by Thordon Bearings, represents a significant leap forward in sterntubeless technology. This design features a seawater-lubricated bearing, a Wärtsilä forward shaft seal, a Water Quality Package, and a bulkhead seal. These key features address the limitations of traditional sterntube designs by providing a more efficient and environmentally friendly propulsion system. The seawater-lubricated bearing eliminates the need for oil lubrication, reducing the risk of oil spills and enhancing the vessel’s environmental performance. Additionally, the shorter propeller shaft allows for easier maintenance and inspection, further improving operational efficiency [Source: ABS-Approved Sterntube-less Ship Concept to Save Shipowners Thousands While Keeping Oceans Clean].

The official launch of the T-BOSS design in September 2024 marked a milestone in the sterntubeless ship concept. The industry’s response has been overwhelmingly positive, with shipowners and yards expressing significant interest in adopting this innovative design. The T-BOSS design’s ability to reduce operational costs, enhance safety, and minimize environmental impact has generated considerable enthusiasm. Thordon Bearings’ commitment to advancing maritime technology through the T-BOSS design positions the company at the forefront of the sterntubeless ship revolution [Source: Thordon Reports Significant Interest For Sterntubeless Ships With Seawater-lubricated Bearing In ABS Podcast].

Global Interest and Quotation Requests

The sterntubeless ship concept has garnered significant global interest, with shipowners and yards worldwide expressing a strong inclination towards this innovative technology. The concept, which replaces the traditional sterntube with a seawater-lubricated bearing system, is seen as a potential game-changer in maritime design.

Major shipbuilding yards have received numerous quotation requests, indicating a growing demand for this technology. For instance, Thordon Bearings has reported significant interest from shipowners and yards globally, with many expressing a desire to integrate the sterntubeless design into their newbuild projects.

Owner interest is particularly strong in regions with extensive maritime activities, such as Europe and Asia. Shipowners in these regions are keen to capitalize on the potential market opportunities and expected CAPEX and OPEX savings. The sterntubeless concept offers substantial cost benefits, as it eliminates the need for oil-lubricated sterntubes and reduces maintenance requirements.

The environmental and operational benefits of the sterntubeless ship concept are also a significant draw. The design features a seawater-lubricated bearing, a Wärtsilä forward shaft seal, a Water Quality Package, and a bulkhead seal, which enhance the vessel’s sustainability and efficiency. This design not only reduces the vessel’s ecological footprint but also improves operational efficiency, leading to longer service intervals and reduced downtime.

Overall, the sterntubeless ship concept represents a significant shift towards more sustainable and efficient maritime technology. As shipowners and yards continue to explore this innovative design, the sterntubeless concept is poised to become a standard feature in newbuild vessels, contributing to a greener and more efficient maritime industry [Source: Thordon Bearings].

Compliance and Technological Advancements

The T-BOSS design has been meticulously crafted to adhere to existing ABS class rules, ensuring that it meets all necessary regulatory standards for ship design and safety. This compliance is a testament to Thordon Bearings’ commitment to innovation while maintaining the highest levels of maritime safety [Source: Case Study for Sterntubeless Design].

The sterntubeless design features a seawater-lubricated bearing, a Wärtsilä forward shaft seal, a Water Quality Package, and a bulkhead seal. This advanced design incorporates water-lubricated shaft lines, which eliminate the need for oil-lubricated stern tubes, thereby reducing the risk of oil spills and enhancing environmental sustainability [Source: ABS-Approved Sterntube-less Ship Concept to Save Shipowners Thousands While Keeping Oceans Clean].

Additionally, the design includes fuel-efficient technologies that further contribute to its operational efficiency. The sterntubeless ship concept significantly reduces maintenance costs and operational expenses, making it a cost-effective solution for shipowners [Source: All New Ships Should Be Built to a Seawater-Lubricated Sterntubeless Ship Design]. The ease of plan approval for the T-BOSS design streamlines the certification process, accelerating the adoption of this technology and paving the way for a greener and more efficient maritime future [Source: All New Ships to Be Built Without a Sterntube].

Challenges and Collaborative Efforts

The sterntubeless ship concept, while revolutionary, faced several initial challenges, including regulatory hurdles and industry skepticism. Regulatory bodies had to adapt to the new design, ensuring it met safety and environmental standards. Industry skepticism was addressed through extensive testing and demonstration of the concept’s benefits, such as reduced maintenance and improved fuel efficiency [Source: ABS Approved Sterntube-less Ship Concept].

Organizations like ABS, SDARI, and NTUA played pivotal roles in overcoming these challenges. ABS provided the necessary approvals, ensuring the sterntubeless design was safe and compliant with international standards. SDARI and NTUA conducted extensive research and testing, validating the design’s performance and reliability. Their efforts were crucial in gaining industry acceptance and regulatory approval [Source: Case Study for Sterntubeless Design].

Collaborative efforts between Thordon Bearings, Wärtsilä, and other stakeholders, including shipyards and naval architects, were essential in promoting the sterntubeless ship concept. These partnerships facilitated knowledge sharing, joint testing, and the development of best practices. Thordon Bearings and Wärtsilä, in particular, worked closely to integrate their technologies, creating a seamless and efficient sterntubeless system [Source: Sterntube-less Ship with Thordon COMPAC].

The T-BOSS design’s versatility has opened up new applications beyond conventional ships. Its potential impact extends to offshore platforms, naval vessels, and even specialized cargo ships. This adaptability demonstrates the T-BOSS design’s versatility and its potential to revolutionize various sectors of the shipping industry [Source: Blue Ocean Alliance Introduces Seawater-Lubricated Sterntube-Less Ship Design].

Conclusion

The sterntubeless ship concept, as exemplified by the T-BOSS design, represents a significant advancement in maritime technology. With its immediate cost savings, environmental benefits, and compliance with industry standards, it is poised to transform the shipping industry. The collaboration between Thordon Bearings and Wärtsilä, along with global efforts to promote this technology, ensures its widespread adoption and impact.

Sources

- AJOT – All New Ships to Be Built Without a Sterntube

- gCaptain – Thordon Reports Significant Interest For Sterntubeless Ships With Seawater-lubricated Bearing In ABS Podcast

- Safety4Sea – Blue Ocean Alliance Introduces Seawater-Lubricated Sterntube-Less Ship Design

- Ship Management International – All New Ships Should Be Built to a Seawater-Lubricated Sterntubeless Ship Design

- Eagle – Case Study for Sterntubeless Design

- Thordon Bearings – ABS-Approved Sterntube-less Ship Concept to Save Shipowners Thousands While Keeping Oceans Clean

- Thordon Bearings – Sterntube-less Ship with Thordon COMPAC

Leave a Reply