- Digital twin offshore management technology creates virtual replicas of physical offshore assets that update in real-time

- Maritime industry applications provide valuable lessons for offshore oil and gas operations

- Predictive maintenance through digital twins can reduce downtime by up to 20%

- Integration with IoT sensors and AI enables smarter decision-making for offshore operations

- Overcoming technical challenges in harsh environments is critical for successful implementation

Introduction

Digital twin offshore management is revolutionizing how we monitor, maintain, and optimize offshore assets in the oil and gas industry. As a cornerstone of Maritime 4.0, digital twin technology creates virtual replicas of physical assets that update in real-time, enabling unprecedented levels of predictive maintenance and operational efficiency. This technology bridges the physical and digital worlds, allowing operators to visualize, simulate, and predict the behavior of offshore assets with remarkable accuracy.

Understanding Digital Twin Technology for Offshore Management

What Is a Digital Twin in Offshore Management?

A digital twin in the maritime and offshore domain represents a comprehensive virtual replica of a physical asset that incorporates real-time data to mirror the current state, behavior, and performance of its physical counterpart. While the concept may seem straightforward, a true digital twin requires three essential components:

- A detailed model of the system

- Bidirectional data flow between the physical system and the model

- Model updates based on real-time system data

This distinction is crucial, as many implementations labeled as “digital twins” in the maritime industry focus primarily on modeling alone, neglecting the critical aspects of bidirectional data flow and dynamic model updates.

Digital twins range from representations of specific components (such as engines or propulsion systems) to comprehensive models of entire vessels or offshore structures. At Digital Twin Marine, for instance, digital replicas of vessels are created using advanced technologies including 360° cameras, laser scanners, and photogrammetry software to capture the physical characteristics with high fidelity.

Digital Twin Evolution Within Maritime 4.0

Maritime 4.0 represents the maritime industry’s adaptation of Industry 4.0 principles, emphasizing digitalization, connectivity, and data-driven decision-making. Within this framework, digital twins serve as a cornerstone technology that connects systems throughout the asset lifecycle, from design through construction and maintenance.

The evolution of digital twins in the maritime sector has been marked by increasing sophistication and integration capabilities. Early implementations focused primarily on static models for design visualization, while contemporary digital twins incorporate dynamic data flows, predictive analytics, and even elements of cognition. As offshore-tech-maritime-evolution highlights, the maritime industry has played a significant role in advancing this technology.

As digital twin technology advances, it has the potential to enable fully autonomous functions with zero human input—making optimal data-based decisions for the asset in various situations.

Maritime Digital Twin Applications for Predictive Maintenance

From Reactive to Digital Twin-Powered Predictive Maintenance

One of the most compelling applications of digital twin technology in offshore asset management is the shift from reactive to predictive maintenance strategies. Traditional maintenance approaches in the offshore industry have often been reactive (responding to failures) or preventive (based on fixed schedules), both of which can lead to inefficiencies and unnecessary costs.

Digital twins enable a more sophisticated approach by continuously monitoring the condition of equipment and systems through sensors, predicting potential failures before they occur. This predictive capability is particularly valuable for offshore assets, where equipment failures can result in costly downtime, safety risks, and environmental hazards.

Case Study: Digital Twin Engine Monitoring in Maritime Vessels

Several cases demonstrate the effectiveness of digital twins for predictive maintenance in maritime applications. For instance, digital twins of cargo ship engines can monitor vital parameters such as temperature, pressure, vibration, and fuel consumption in real-time. By analyzing this data against historical patterns and physics-based models, the digital twin can identify early warning signs of degradation or malfunction.

In one implementation, a shipping company reduced engine downtime by 25% and maintenance costs by 15% by implementing digital twin technology for their fleet. The system was able to predict impending failures in cooling systems and fuel injectors days before they would have caused operational issues.

The ai-green-tech-and-cybersecurity-the-maritime-industrys-2025-game-plan blog highlights how the integration of AI and IoT in predictive maintenance has become a key focus for the maritime industry in 2025.

Similar approaches can be applied to offshore oil and gas assets, particularly for critical equipment such as:

- Drilling equipment

- Pumping systems

- Power generation units

- Compressors and separators

Digital Twin Challenges in Offshore Environments

Harsh Environmental Challenges for Digital Twin Implementation

Implementing digital twins in offshore oil and gas environments presents unique challenges due to the harsh operating conditions. Offshore platforms face extreme weather, saltwater corrosion, and high vibration levels, all of which can affect sensor reliability and data quality.

These environmental factors make it difficult to create high-precision 3D digital models for multi-scale analysis, necessary for accurate simulation of damage evolution and effective machine learning-based state evaluation. The complexity of offshore equipment, combined with the impact of variable loads and harsh marine environments, leads to rapid performance degradation and frequent failures, further complicating the modeling process.

Digital Twin Data Integration Complexities

Integration challenges also arise when attempting to create a cohesive digital twin from multiple subsystems and data sources. The tradition of siloed software systems and data handling in the maritime and offshore industries poses a significant obstacle to creating comprehensive digital twins.

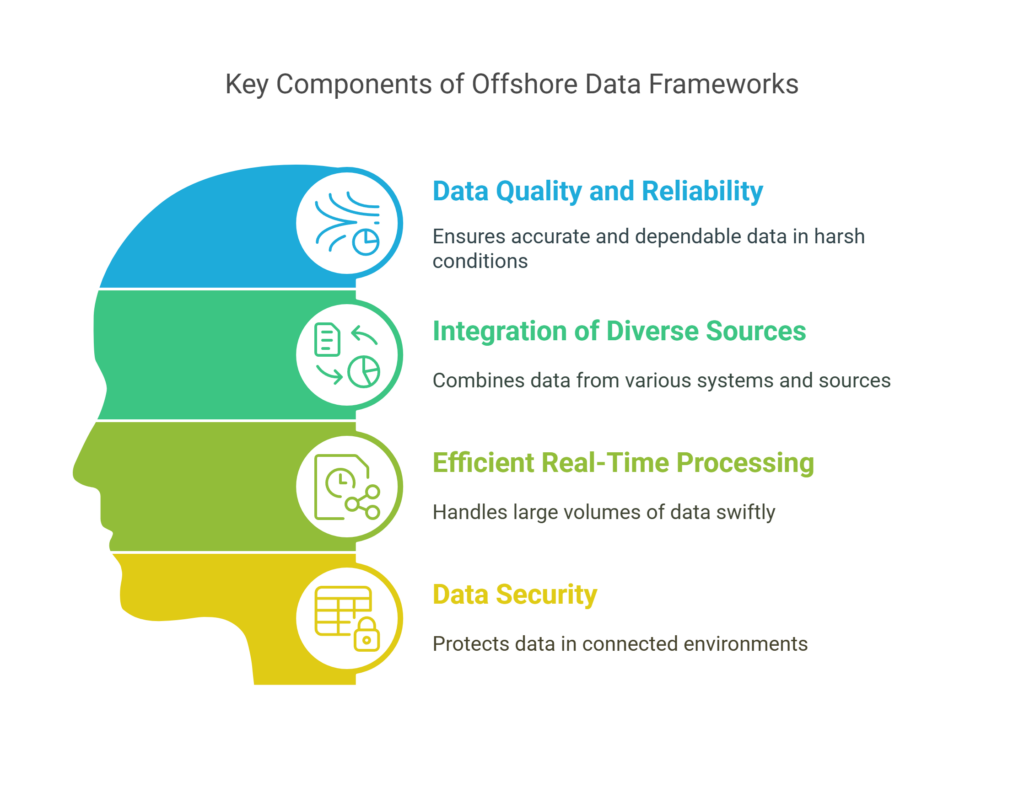

To address these challenges, offshore operators need robust data frameworks that can:

- Ensure data quality and reliability in harsh conditions

- Integrate information from diverse sources and systems

- Process large volumes of real-time data efficiently

- Maintain data security in connected environments

As noted in oil-gas-investment-2025-dividends-risks-geopolitics, these technical risks must be managed alongside geopolitical considerations in offshore operations.

IoT and AI Synergy in Offshore Digital Twin Management

The Role of IoT Sensors in Digital Twin Offshore Management

Internet of Things (IoT) sensors form the foundation of effective digital twin implementations in offshore environments. These sensors capture real-time data on various operational parameters, including:

- Equipment temperature and pressure

- Structural strain and vibration

- Environmental conditions

- Power consumption and efficiency

- Fluid flow rates and composition

The quality and reliability of this sensor data directly impact the accuracy and effectiveness of the digital twin. Advances in sensor technology, including miniaturization, improved durability, and lower power requirements, have made it feasible to deploy comprehensive sensor networks even in challenging offshore environments.

AI-Powered Analytics for Digital Twin Offshore Assets

Artificial intelligence and machine learning technologies transform raw sensor data into actionable insights within digital twin systems. AI algorithms can identify patterns, detect anomalies, predict future conditions, and recommend optimal actions based on the continuous stream of data from the physical asset.

As highlighted in ai-agents-2025-transformation, AI agents have transformative potential in industrial applications like offshore operations. These AI capabilities enhance digital twins in several ways:

- Predictive analytics for equipment failure prevention

- Optimization of operational parameters for efficiency

- Automated decision-making for routine operations

- Scenario simulation for risk assessment and planning

- Continuous learning and improvement from operational data

Edge Computing for Real-Time Digital Twin Processing

Edge computing plays a crucial role in enabling digital twins for offshore assets, particularly in remote locations with limited connectivity. By processing data close to its source, edge computing solutions reduce latency, bandwidth requirements, and dependency on constant connectivity.

This capability is especially valuable for offshore platforms, where satellite communications may be limited or unreliable. Edge computing enables digital twins to maintain critical functionality even during communication disruptions, ensuring continuous monitoring and decision support for essential operations.

Digital Twin Offshore Management Roadmap

Step 1: Define Digital Twin Offshore Objectives

The first step in implementing digital twins for offshore assets is to clearly define the objectives and scope of the initiative. Organizations should identify:

- Primary business goals (cost reduction, safety improvement, etc.)

- Critical assets or systems to be modeled

- Level of detail and functionality required

- Integration requirements with existing systems

- Key performance indicators (KPIs) for measuring success

Starting with a focused pilot project rather than attempting to create a comprehensive digital twin of the entire operation often leads to better results. This approach allows organizations to demonstrate value quickly while building expertise and support for broader implementation.

Step 2: Establish Digital Twin Data Infrastructure

Developing a robust data infrastructure is essential for successful digital twin implementation. This infrastructure should support:

- Data collection from diverse sources and sensors

- Data validation, cleaning, and preprocessing

- Secure data storage and management

- Data integration across operational systems

- Efficient data access and visualization

As noted in state-controlled-oil-reserves-global-power-future-trends, the strategic importance of digital twins in global energy markets cannot be overstated, making data infrastructure a critical investment.

Step 3: Develop and Validate Digital Twin Models

Developing accurate models of offshore assets requires collaboration between domain experts and modeling specialists. These models typically incorporate:

- Physical characteristics and behaviors

- Operational parameters and constraints

- Environmental interactions

- Degradation and failure mechanisms

- Control systems and automation

Validation is a critical step in ensuring that digital twin models accurately represent their physical counterparts. This process involves comparing model predictions with real-world observations across various operating conditions and scenarios.

Step 4: Implement and Scale Digital Twin Offshore Solutions

After validating the digital twin models, the next step is to implement them in operational contexts. This implementation typically involves:

- Deploying necessary hardware (sensors, edge computing devices)

- Installing and configuring software systems

- Training operations and maintenance personnel

- Establishing workflows for using digital twin insights

- Monitoring performance and refining the system

As expertise and confidence grow, organizations can gradually scale their digital twin implementations to encompass additional assets, systems, and use cases.

Step 5: Measure Digital Twin ROI and Optimize

Measuring return on investment (ROI) is essential for sustaining support for digital twin initiatives. Organizations that have adopted digital twins report significant benefits, such as a nearly 20% reduction in costs. These cost savings can result from various factors, including reduced downtime, optimized maintenance, improved energy efficiency, and extended asset life.

Key metrics for evaluating digital twin ROI include:

- Reduction in unplanned downtime

- Maintenance cost savings

- Energy efficiency improvements

- Extended asset life

- Safety incident reduction

- Operational productivity gains

Future Trends in Digital Twin Offshore Technology

Autonomous Digital Twins for Offshore Management

The next generation of digital twins will feature increasing levels of autonomy, enabling them to make decisions and take actions with minimal human intervention. These autonomous digital twins will incorporate advanced AI capabilities, including:

- Self-diagnosis and self-healing

- Continuous self-optimization

- Autonomous adaptation to changing conditions

- Proactive risk identification and mitigation

- Collaborative decision-making with other systems

As highlighted in nuclear-power-in-maritime-shipping-decarbonization-challenges, digital twins will play an important role in sustainable energy solutions, including more efficient and environmentally friendly offshore operations.

Digital Twin Ecosystems for Offshore Asset Management

Future digital twins will increasingly operate as part of broader ecosystems rather than as isolated systems. These ecosystems will connect digital twins across organizations, supply chains, and industries, enabling new levels of collaboration, optimization, and innovation.

Key aspects of these emerging digital twin ecosystems include:

- Standardized data formats and interfaces

- Cloud-based platforms for integration and collaboration

- Marketplace models for digital twin applications and services

- Cross-organizational data sharing and insights

- Industry-specific reference architectures and frameworks

Digital Twin Regulatory Evolution

As digital twin technology becomes more prevalent in offshore operations, regulatory frameworks will evolve to address associated challenges and opportunities. Future regulations may address aspects such as:

- Data ownership and sharing requirements

- Cybersecurity standards for connected assets

- Certification requirements for digital twin accuracy

- Guidelines for autonomous decision-making systems

- Liability frameworks for digital twin-informed decisions

Organizations that proactively engage with regulators and industry associations in shaping these frameworks will be better positioned to navigate the evolving regulatory landscape.

Conclusion

Digital twin offshore management offers a transformative approach to asset optimization, drawing on maritime industry successes to enhance predictive maintenance and operational efficiency. By addressing technical challenges and leveraging IoT and AI integration, the offshore sector can unlock significant ROI and operational improvements.

The journey toward comprehensive digital twin implementation requires a strategic approach, beginning with clear objectives and building through data infrastructure, model development, implementation, and continuous improvement. Organizations that successfully navigate this journey can achieve substantial benefits in terms of cost reduction, efficiency improvement, safety enhancement, and environmental performance.

The future of digital twins lies in scalability, interoperability, and emerging technologies like edge computing and autonomous systems, paving the way for smarter, more resilient offshore operations. As the technology continues to mature and integration challenges are addressed, digital twins will likely become an essential component of offshore asset management strategies across the global energy sector.

Leave a Reply