WinGD’s X-DF-A Ammonia-Fueled Engine: A Game-Changer in Marine Power Solutions

Introduction to WinGD and the X-DF-A Engine

WinGD, a Swiss marine power company, has been a pioneer in developing innovative marine power solutions, particularly in dual-fuel engines. The company’s commitment to sustainability and technological advancement is evident in its development of the X-DF-A ammonia-fueled engine. This engine represents a significant milestone in the maritime industry, aiming to reduce greenhouse gas emissions and provide a viable alternative to traditional marine fuels.

The X-DF-A engine is based on the well-established diesel-cycle concept, a cornerstone of WinGD’s engine designs for decades. However, it incorporates new technologies specifically developed for efficient ammonia injection and combustion. These innovations include advanced fuel handling systems and emission control mechanisms that set the X-DF-A apart from conventional marine engines. According to Marine Log, the X-DF-A platform has demonstrated promising results in early testing, with combustion efficiency, emissions, and pilot consumption all within expected ranges.

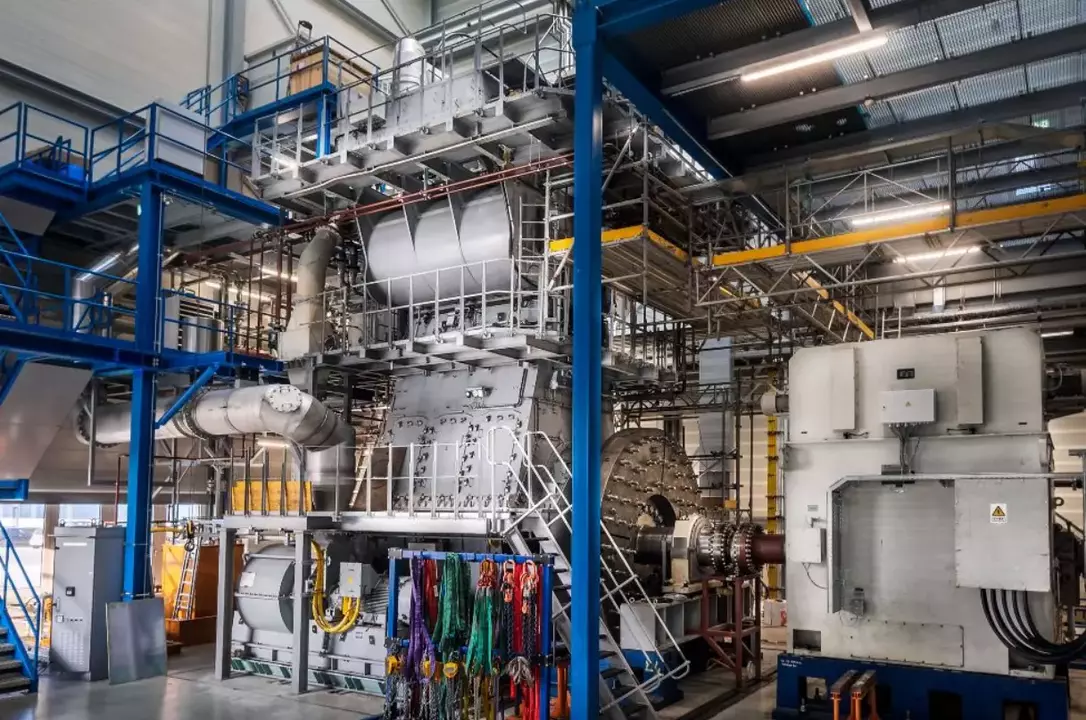

WinGD’s journey in ammonia engine development began in 2019, with the goal of creating a sustainable and efficient marine power solution. The company has since made significant progress, culminating in the successful early testing of the X-DF-A engine. As reported by Hellenic Shipping News, a 52-bore single-cylinder version of the X-DF-A engine is currently undergoing trials at WinGD’s Engine Research and Innovation Centre (ERIC) in Winterthur. The final validation of the engine is expected to be completed in time for the first engine deliveries in June 2025.

The integration of these new technologies into the X-DF-A engine has resulted in a power solution that not only meets but exceeds the environmental and operational demands of the maritime industry. The engine’s ability to efficiently burn ammonia, a carbon-neutral fuel, positions it as a key player in the transition towards greener shipping. With nearly 30 orders already secured for the X-DF-A engine across various maritime sectors, including bulk carriers, containerships, and LPG/ammonia carriers, WinGD is well on its way to revolutionizing marine power solutions.

Technological Innovations in the X-DF-A Engine

The X-DF-A engine, developed by WinGD, represents a significant leap in marine propulsion technology, particularly in the context of sustainable and efficient fuel usage. At its core, the engine operates on the diesel-cycle principle, which involves the compression of air to a high temperature, followed by the injection of fuel that ignites due to the heat generated. This process is highly efficient and forms the basis of the X-DF-A’s operation. However, what sets the X-DF-A apart is its ability to utilize ammonia as a primary fuel, a feature that requires innovative technological advancements in fuel injection and combustion.

Ammonia, a compound of nitrogen and hydrogen, presents unique challenges and opportunities in combustion. The X-DF-A engine incorporates advanced fuel injection systems designed to handle ammonia’s properties, such as its high auto-ignition temperature and low flame speed. These systems ensure precise and efficient ammonia injection, optimizing combustion and minimizing emissions. The engine’s combustion process is further enhanced by technologies that stabilize the flame and improve the overall combustion efficiency, even under varying load conditions.

Emission control is another area where the X-DF-A engine excels. Traditional marine engines often struggle with NOx and SOx emissions, but the X-DF-A’s design significantly reduces these pollutants. The engine employs selective catalytic reduction (SCR) systems and exhaust gas recirculation (EGR) to lower NOx emissions, while the use of ammonia as a fuel inherently reduces SOx emissions, as ammonia contains no sulfur. These innovations align with the stringent regulations of Emission Control Areas (ECAs), making the X-DF-A a compliant and environmentally friendly option for modern shipping.

Fuel handling innovations are also a critical component of the X-DF-A engine. Ammonia, being a toxic and corrosive substance, requires specialized storage and handling systems. The X-DF-A engine integrates robust fuel handling technologies that ensure safe and efficient ammonia storage, transfer, and injection. These systems are designed to prevent leaks and manage the risks associated with ammonia, ensuring the safety of both the crew and the environment.

The integration of these technologies contributes to the X-DF-A engine’s overall efficiency and environmental benefits. By combining the diesel-cycle’s inherent efficiency with advanced ammonia combustion and emission control technologies, the X-DF-A engine offers a sustainable and powerful solution for marine propulsion. Its ability to reduce greenhouse gas emissions and comply with stringent environmental regulations positions it as a key player in the transition towards greener shipping. According to WinGD, the X-DF-A engine’s early testing has shown promising results, with combustion efficiency and emissions within expected ranges, further validating its potential as a game-changer in marine propulsion technology.

Early Testing and Performance Milestones

The early testing of WinGD’s X-DF-A ammonia-fueled engine at the Engine Research and Innovation Centre (ERIC) in Winterthur, Switzerland, has marked a significant milestone in the development of next-generation marine propulsion systems. The 52-bore single-cylinder version of the X-DF-A engine demonstrated promising results, with combustion efficiency, emissions, and pilot consumption aligning closely with performance expectations [Hellenic Shipping News].

The rapid validation of the ammonia combustion system under engine conditions is a critical achievement. This success underscores the engine’s ability to handle ammonia as a fuel, which is pivotal for reducing greenhouse gas emissions in the maritime industry. The X-DF-A engine’s performance in these early tests indicates that it can achieve high combustion efficiency while maintaining low emissions, a key requirement for future maritime regulations [Marine Log].

Moreover, the integration of advanced technologies for ammonia injection and combustion has been validated during these tests. The engine’s ability to switch seamlessly between diesel and ammonia modes without loss of power or speed is a testament to the robustness of the X-DF-A design [WinGD]. This capability not only enhances operational flexibility but also ensures that the engine can meet the diverse needs of modern shipping.

The successful early testing of the X-DF-A engine at ERIC is a crucial step towards its commercialization. It provides a solid foundation for further development and optimization, paving the way for the engine’s deployment in real-world applications. The results from these tests are a clear indication that the X-DF-A engine is on track to become a game-changer in the maritime industry, offering a sustainable and efficient alternative to conventional marine engines [Offshore Energy].

Validation and Optimization

Single-cylinder testing plays a crucial role in validating the ammonia combustion system of WinGD’s X-DF-A engine. This phase is essential for understanding the combustion characteristics, emissions, and efficiency of the engine when running on ammonia. The initial tests conducted at WinGD’s Engine Research and Innovation Centre (ERIC) in Winterthur have shown promising results, with combustion efficiency, emissions, and pilot consumption all within expected ranges [Hellenic Shipping News].

Transitioning from single-cylinder testing to full-scale engine validation is a significant step in the development process. This phase involves scaling up the technology to a multi-cylinder engine, which allows for a more comprehensive evaluation of the engine’s performance under real-world conditions. The full-scale validation will also test the integration of various subsystems, including fuel injection and emission control systems, ensuring that the engine operates efficiently and meets stringent environmental standards [Port Technology].

WinGD has planned multi-cylinder engine tests at its Global Research Centre in Shanghai. These tests will focus on validating the control systems that manage the ammonia injection and combustion processes. The successful validation of these systems is critical for the engine’s overall performance and reliability. The results from these tests will provide valuable insights into the engine’s operational capabilities and help optimize its design for commercial deployment [Marine Log].

Orders and Market Impact

WinGD has secured nearly 30 orders for its X-DF-A ammonia-fueled engines, marking a significant milestone in the maritime industry. These orders span various segments, including bulk carriers, containerships, tankers, and LPG/ammonia carriers. The adoption of the X-DF-A engine across these diverse vessel types underscores its versatility and the industry’s growing confidence in ammonia as a viable marine fuel [WinGD].

The market impact of these orders is substantial. By transitioning to ammonia-fueled engines, shipowners can significantly reduce greenhouse gas emissions, aligning with stricter environmental regulations. The X-DF-A engine’s ability to operate efficiently on ammonia positions WinGD as a leader in the push towards decarbonization in the maritime sector [Offshore Energy].

WinGD has outlined a clear timeline for the delivery and market entry of the X-DF-A engines. The first engines are expected to be delivered by the end of 2024, with full-scale commercial availability projected for 2025. This strategic timeline allows WinGD to capitalize on the increasing demand for cleaner propulsion technologies while ensuring rigorous testing and optimization of the engines [WinGD].

The successful early running of the X-DF-A engine at WinGD’s Engine Research and Innovation Centre (ERIC) in Winterthur has further bolstered confidence in its performance. The engine’s combustion efficiency, emissions control, and pilot consumption have all met or exceeded expectations, paving the way for its widespread adoption [Hellenic Shipping News].

In conclusion, the nearly 30 orders for WinGD’s X-DF-A engines represent a significant step forward in the maritime industry’s transition to cleaner fuels. The engine’s innovative design, coupled with WinGD’s strategic delivery timeline, positions the company as a key player in the global effort to reduce shipping emissions. The market impact of these orders is expected to be profound, driving further innovation and adoption of ammonia as a sustainable marine fuel.

Conclusion

The successful early testing of WinGD’s X-DF-A ammonia-fueled engine marks a pivotal moment in the development of clean and efficient marine power solutions. The technological advancements and the company’s strategic orders position WinGD at the forefront of the maritime industry.

Sources

- Marine Log – WinGD Records Successful Early Running on X-DF-A Ammonia-Fueled Test Engine

- Hellenic Shipping News – WinGD Records Successful Early Running on X-DF-A Ammonia-Fuelled Engine

- WinGD – X-DF Dual-Fuel Design

- Offshore Energy – WinGD’s X-DF-A Ammonia Engine Aces Initial Performance Milestone

- Port Technology – WinGD Trials Ammonia-Fuelled X-DF-A Engine

- WinGD – WinGD Seals Ammonia-Fuelled X-DF-A Engine Orders for Chinese Gas Carriers

- Offshore Energy – WinGD’s X-DF-A Engines Set to Power Seven LPG/Ammonia Carriers in China

- WinGD – Products & Solutions: Engines

Leave a Reply